A BRIEF HISTORY OF MANUFACTURING IN NEW JERSEY FROM THE COLONIAL TO MODERN ERAS | PART 2

By Ken Schwemmer, Advocacy and Operations Support NJMEP

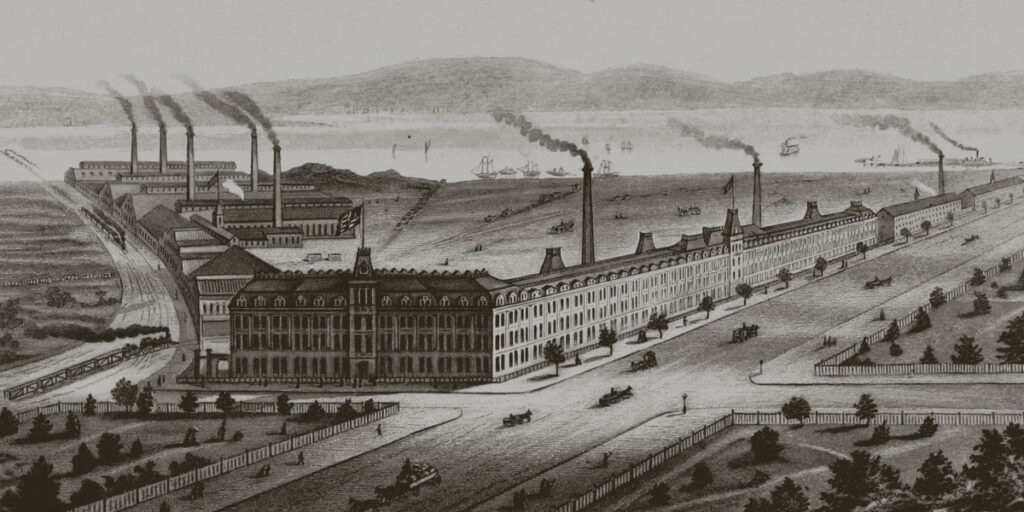

The Singer Sewing Company is probably one of the most famous manufacturing companies to operate in New Jersey. In 1873, Singer moved its New York factory to Elizabeth due to the increasing demand for their products. Despite some setbacks with trying to make improvements to their factory processes, the company doubled production within the first years of opening the Elizabeth factory, and eventually, more than half of the company’s sewing machines were being produced in the Elizabeth factory. The company’s Elizabeth plant became so successful that by the mid-1880s it was producing six to seven thousand sewing machines a week and employed around three thousand workers. This multinational firm, which had numerous factories around the world, wound up having New Jersey supply a good portion of their sewing machines to the world.

Besides Singer, there were other New Jersey-based manufacturers that had a major impact on America and its landscape, such as Roebling. In the late nineteenth and early twentieth centuries, Roebling was one of the most famous steel cable manufacturers in the world and located in the Trenton area of New Jersey. Founded in 1841 by John A. Roebling, a German immigrant, who was able to patent his process for manufacturing wire rope, Roebling would go on to be part of numerous bridge projects as early as the 1840s. Though Roebling worked on a variety of projects before the Second Industrial Revolution, one of the most famous projects the company completed was the Brooklyn Bridge. John Roebling was contracted to be the chief engineer of the Brooklyn Bridge in 1867, but due to a work accident, that also caused a tetanus infection, John Roebling died on June 6, 1869. This forced John Roebling’s son, Washington Augustus, to take over the project and he started the construction of the bridge on January 3, 1870. After thirteen years, Washington Roebling completed the bridge that his father, John Roebling, had envisioned so many years before. This was all done by a New Jersey manufacturing company, and it produced one of the greatest bridges ever to be seen by that point.

The success of the Brooklyn Bridge project helped contribute to Roebling’s further success and growth. The company continued to grow and become one of the biggest manufacturers of wire cables. Though the original Trenton location for Roebling had been successful, the company needed to find a new location by the beginning of the twentieth century. Charles Roebling, the youngest son of John, decided to buy up 240 acres of land in central New Jersey in 1904 and created a new factory site for the company. This led to the creation of a workers’ village called Roebling, which was one of the many factory towns that New Jersey would have. Roebling’s manufacturing operations had been moved and this is where most of their wire cables would come from, and these manufactured wire cables would be used for a variety of projects—from elevators to the construction of the George Washington Bridge and Golden Gate Bridge. By the twentieth century, Roebling had emerged as one of New Jersey’s most successful manufacturing companies in New Jersey and had become a major supplier to the country for wire cables.

The previous examples were of how New Jersey was able to utilize innovations to improve existing manufacturing industries. However, there were also new manufacturing industries that emerged in New Jersey, such as oil refineries.

Missed A BRIEF HISTORY OF MANUFACTURING IN NEW JERSEY FROM THE COLONIAL TO MODERN ERAS | PART 1? View the last edition of Manufacturing Matters and read more about the Garden State’s history in Manufacturing.