Grassroots effort underway to make face shields for New Jersey healthcare workers

NJ high school robotics team collaborates with private and public sectors and uses 3D printing technology to help ease face shield shortage due to the COVID-19 pandemic.

Newton, New Jersey (March 27, 2020) – It started with an email exchange late on Sunday night. A request from Rutgers New Jersey Medical School student Rohan Sawhney to help make Personal Protective Equipment – specifically face shields for healthcare workers — was sent to James Hofmann, STEM teacher at Newton, NJ High School, and the coach of the Varsity Robotics Team for the past eleven years.

New Jersey currently has the second largest number of confirmed coronavirus cases in the United States.

Hofmann understands the urgent need. His son Justin, a graduate of Newton High School and 2017 graduate of Rutgers NJMS, is currently a third year resident working on the front lines at University Hospital in Newark, NJ.

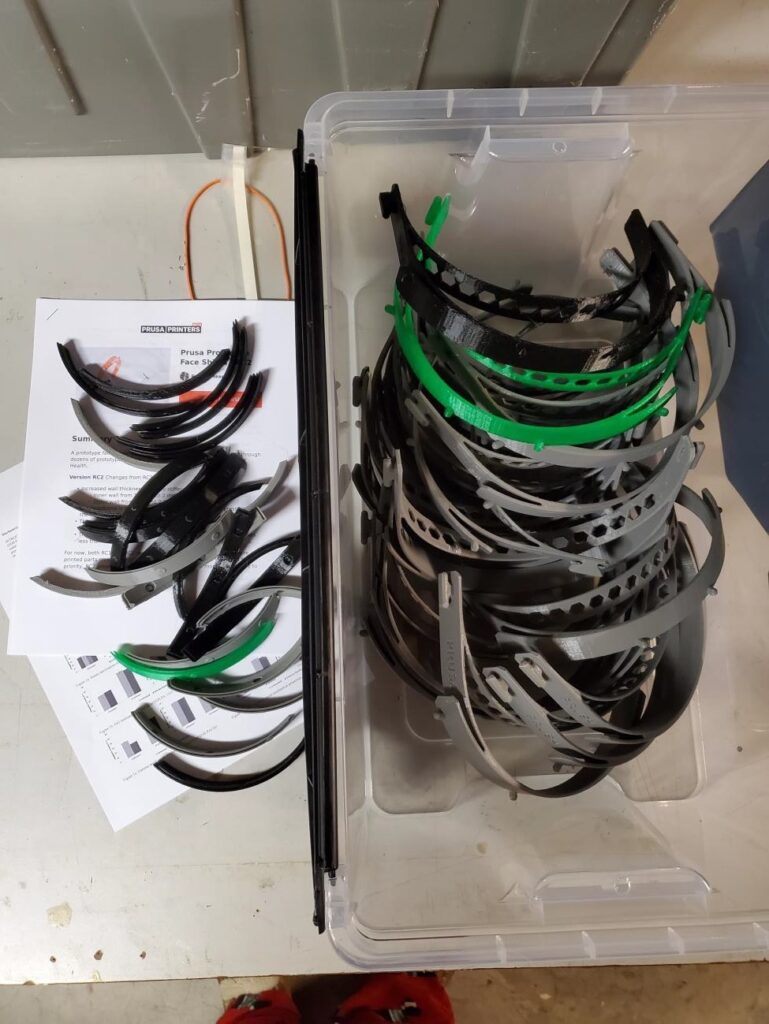

The effort, named “PPE Made in America,” has a goal of making 1,000 face shields locally using 3D printers to make the headband portion. The first step was to obtain approval from Principal Jeffrey Waldron to use the school’s 3D printer. Hofmann then leveraged his network of STEM partners and sent an email describing the project with what materials were needed and the associated costs.

The first to respond was Alex Cable, CEO of Thorlabs, Inc., a Newton-based optical equipment company. Cable said currently their priority project is UV Sterilization Chambers for possible N95 mask reuse. Cable committed his engineering staff to prototype headband samples, and then output on his company’s 3D printers, as well as assist in sourcing PETG .02 (polyethylene terephthalate glycol), a sheet of tough plastic material that completes the face shields. Thomas Sinner’s engineering team at Thorlabs will cut the large PETG sheets into smaller, more manageable sizes.

Mark Maruska and Adam Zuedima of Gravity DesignWorks in Newton volunteered to cut the smaller PETG sheets into finished face shields.

New Jersey Manufacturing Extension Program CEO John Kennedy, Ph.D., also answered the call. NJMEP, a not-for-profit that works with New Jersey’s small to mid-sized manufacturers, is helping with supply chain and sourcing PETG.

David Romano of RoNetco Supermarkets, Inc., owner of eight local ShopRite grocery stores, has pledged financial support, as has Kristin Prigmore of the Prigmore Science Foundation.

Shahram Dabri, STEM Manager of the Education Office at the U.S. Army Picatinny Arsenal in Dover, NJ, is reaching out to his contacts at over 400 New Jersey schools to enlist their support. Last month Picatinny Arsenal sponsored a two-day workshop for more than a dozen NJ teachers with advanced training on 3D printing and CAD, or computer-aided-design. The workshop and a MakerBot 3D printer for their students to use in school were gratis to the teachers.

Several neighboring high schools with robotics teams and 3D printers who are normally competitors are also pitching in to help, including those from Lenape Valley, Mount Olive and Vernon.

“In this crisis, it’s all hands on deck, and great to see everyone come together in the effort” Hofmann said. He added “If any business or school has spare 3D printing capacity, we could sure use your help.”

Contact:

James Hofmann

Newton, NJ Public School District jhofmann@newtonnj.org

Cell: 973-903-9774

STEM Teacher, Newton High School

Coach, Newton High School FIRST Varsity Robotics Team